- Home

-

Product

Product

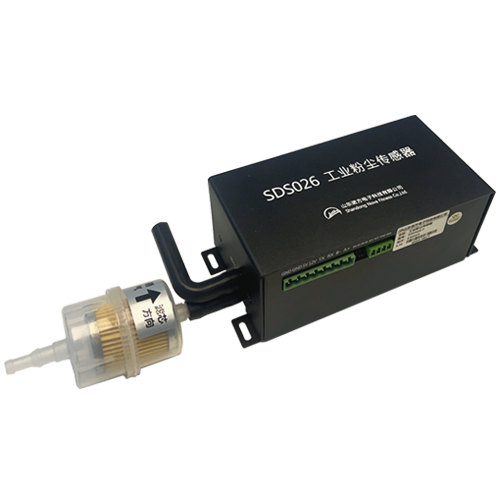

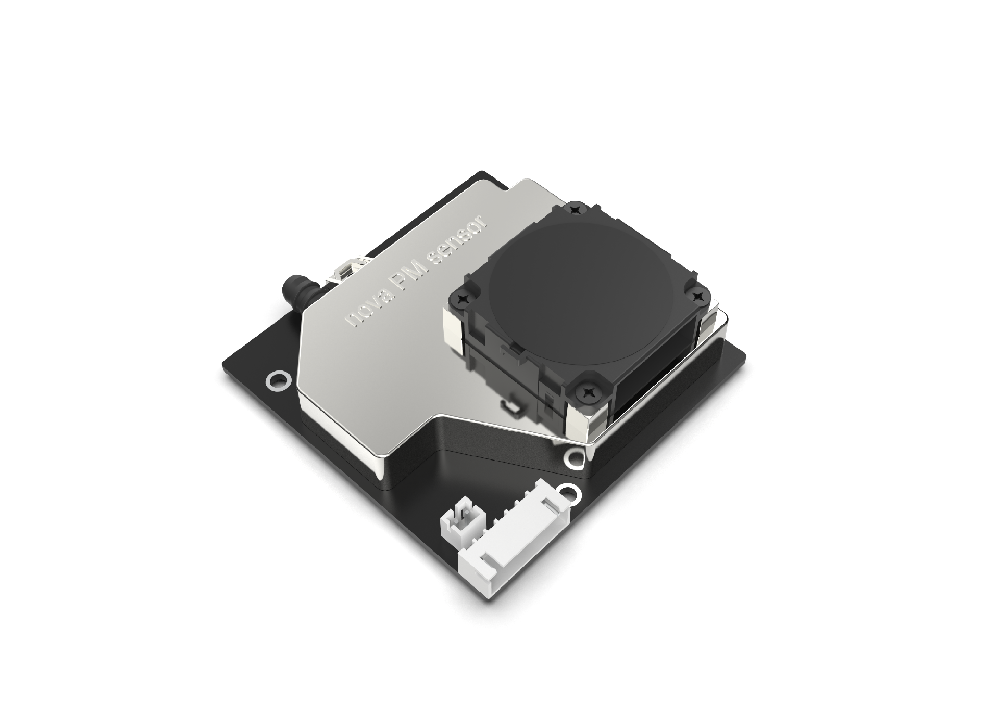

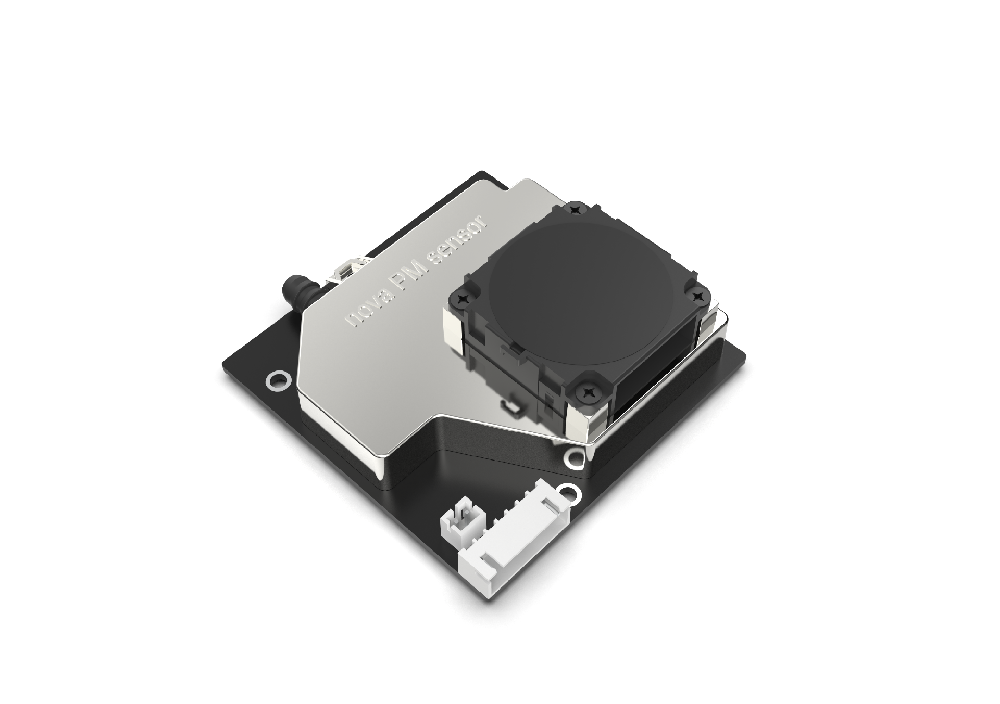

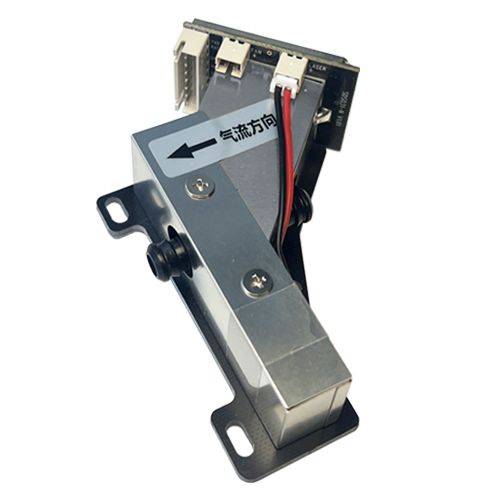

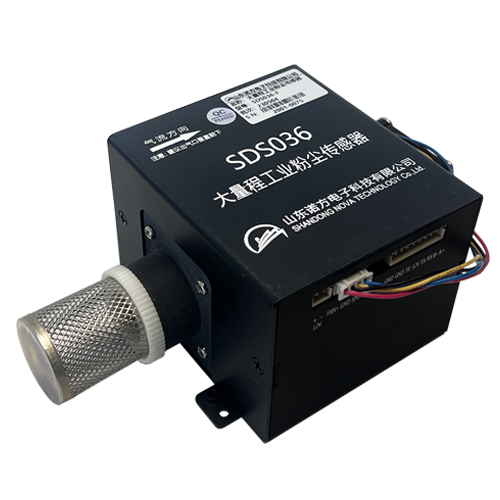

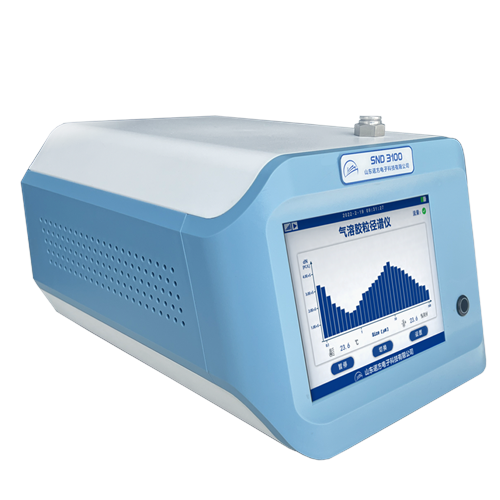

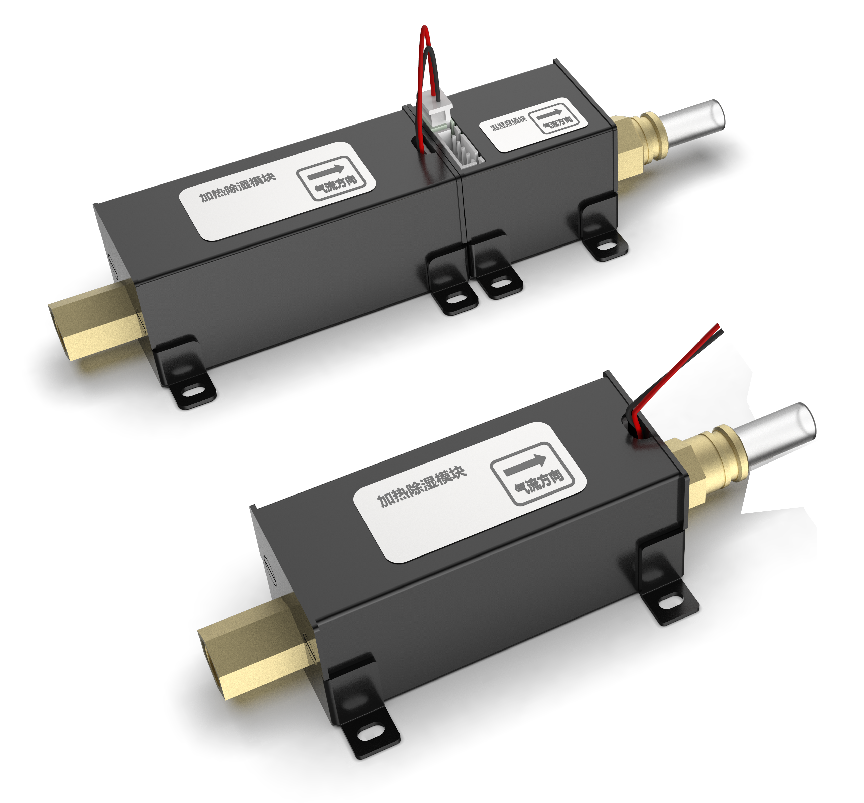

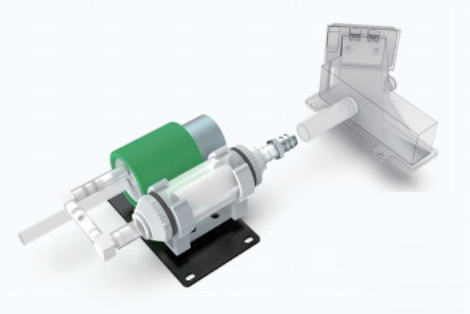

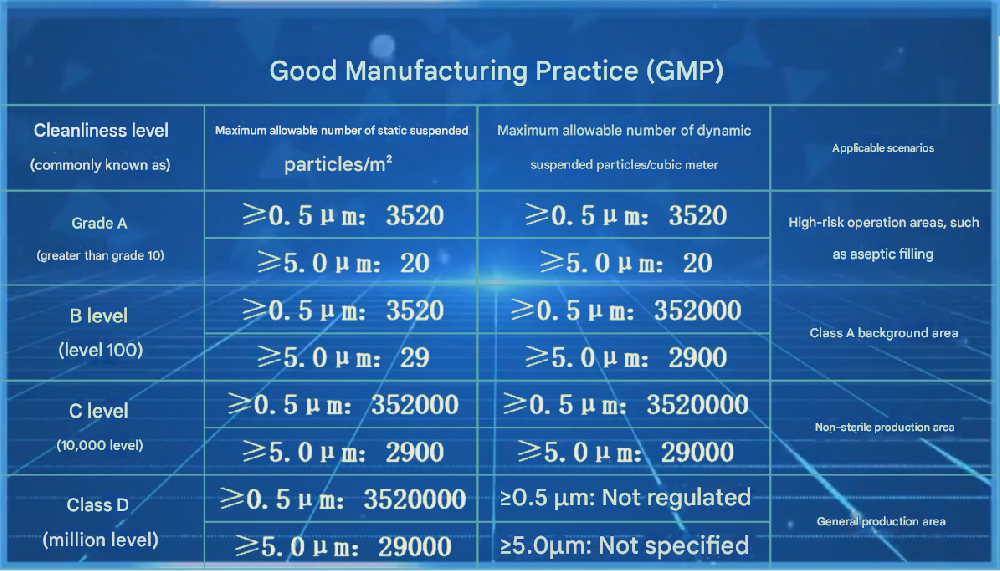

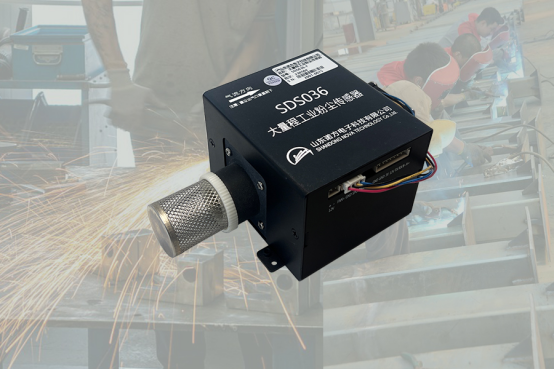

Shandong Nova Technology Co., Ltd. is a research and development enterprise, that specializes in the production of dust sensor, dust particle counter, particle size spectrometer, oil fume sensor, particulate sensor, dust concentration detector. With internationally advanced technology, applied to various places that require particle concentration monitoring, such as environmental protection, industry, catering fumes, laboratories, clean rooms, factory workshops.More+Clean Room Monitoring18 Atmospheric Dust16 High Concentrate Dust17 Particle size spectrum sensor51SensorClean Room Monitoring43 Air Environmental Protection31 High Concentrate Dust15 Particle Size Spectrometer44 Image particle size analyzer48DeviceAccessory45Accessories -

Solution

Solution

Widely used in various places that require particle concentration monitoring, such as environmental protection, industrial environments, catering fumes, laboratories, clean rooms, factory workshops, etc.more+ -

Download

Download

NovaSensor focuses on the particle detection industry and has more than ten years of underlying research and development technology. It has been awarded the title of National Specialized and Innovative "Little Giant" Enterprisemore+ -

News

News

Shandong Nuofang Technology Co., Ltd. is a research and development enterprise co founded by 6 engineering masters from Shandong University. It currently has 100 employees, with 53% of them being research and development personnel. The company has been granted 103 intellectual property rights, including 43 Chinese invention patents and 19 international invention patents.more+ -

About us

About us

NovaSensor's leading products include particulate matter sensors, dust particle counters, dust concentration sensors, oil fume sensors, atmospheric dust concentration detectors, and particle size spectrometers. The technology is internationally advanced and achieves import substitution.more+ - Contact us